Basic Theory

(fjaa140856) Basic Performance Study ← Top / DFV → Details (fjaa140856)

The general premise of material testing is that the test article is nominally a spring. The load frame restrains test article motion on one end. The actuator controls test article motion relative to the baseplate on the other end.

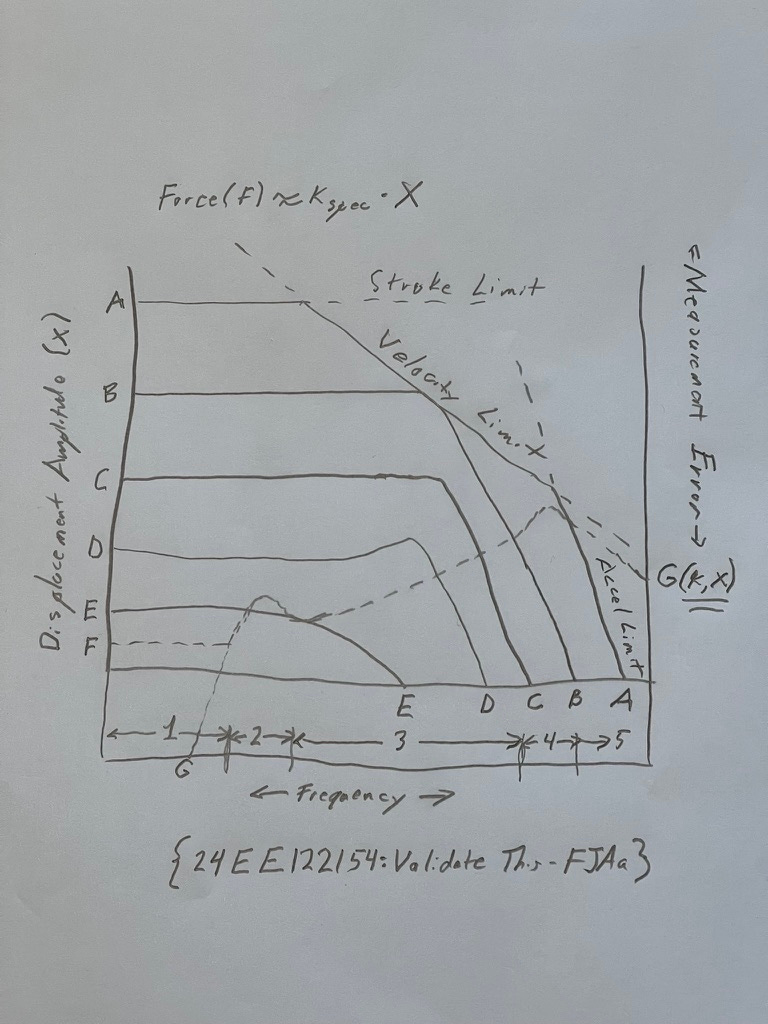

Movement of the actuator applies force to the test article and the load frame. Two actions occur due to that force. First is that the specimen length changes and the reaction frame part of the load frame changes its distance between crosshead and baseplate. Since movement of the actuator requires movement of a mass, part of the force applied to the baseplate is due to the acceleration forces of the actuator. As these forces are not applied to the test article there is a force imbalance applied to the mass of the frame. This causes the frame to accelerate in space.

Total motion can be viewed then in two parts. First, the motion of the center of mass of the frame occurs due to the inertial loading from the actuator. Second, the expansion/contraction of the frame is due to the force applied through the test article. The motion of individual points on the frame depend on the motion of the center of mass plus the motion of the expansion/contraction of the frame. Thus there is substantial uncertainty as to the exact motion of the grip attached to the load cell.

Since movement of the grip requires an inertial force to move its mass, there is a force difference between the two sides of the grip. Since the load cell is applying force to one side of the grip and the test article is applying force to the other side, by definition there must be a difference in force between the actual force in the test article and the force reported by the load cell.