Sine Sweep Analysis

Tag4u: [fjaa154016] < [fjaastub]

Summary

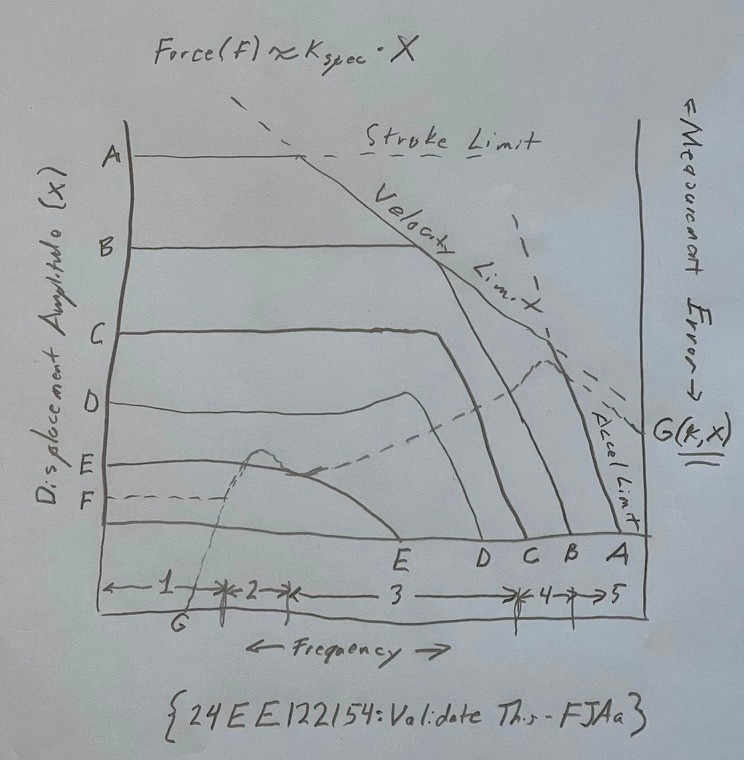

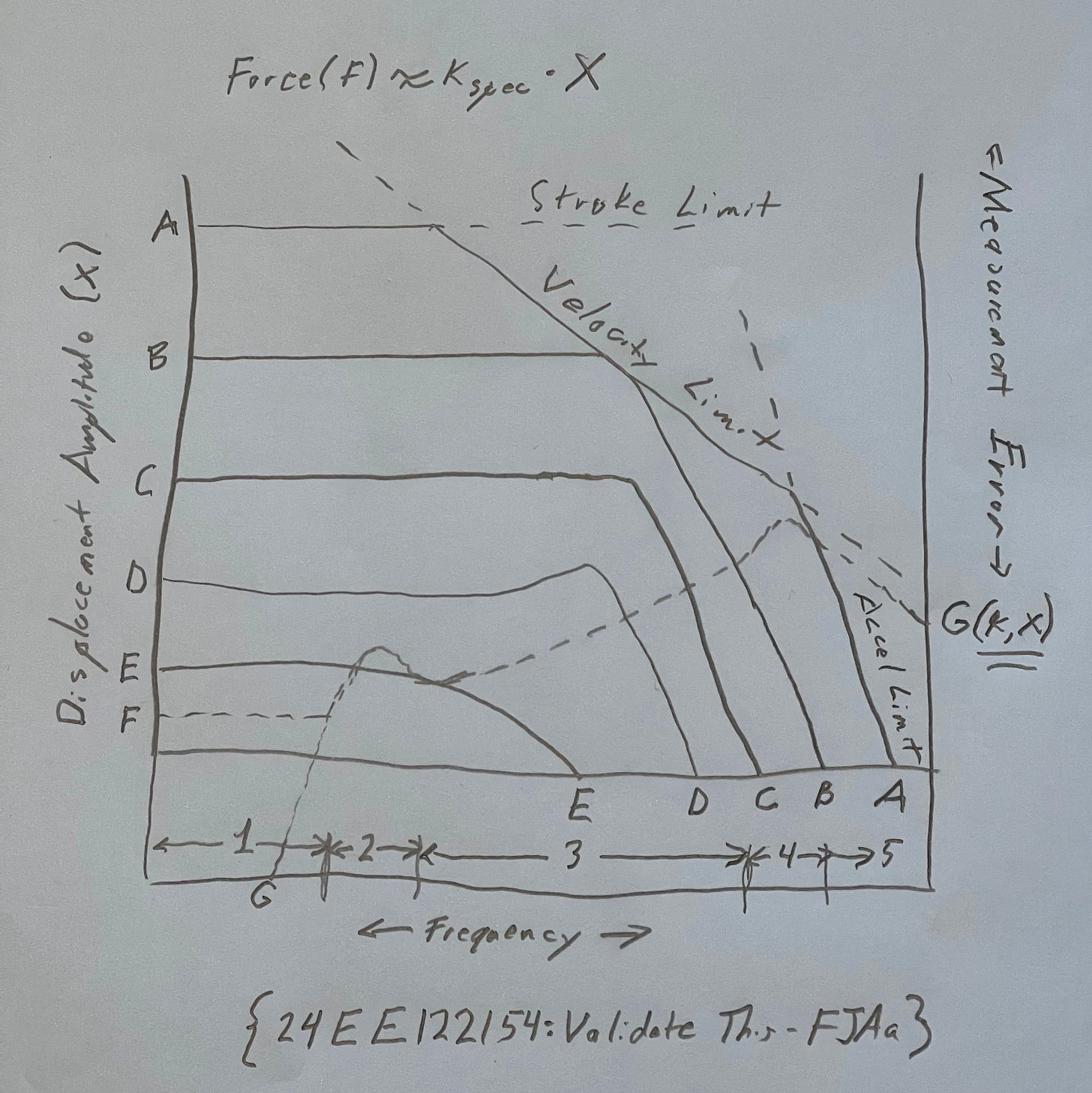

The dynamic performance of a material test machine is quite variable. For any given hardware configuration, the performance depends on frequency, amplitude, and test specimen. Some representative curves are shown in the following figure.

This thread provides detailed information about how to perform a sine sweep analysis in order to determine a portion of one of the sample performance curves shown above. Refer to the Introduction for background regarding why this document is being generated and why associated studies are being conducted in support of this document. Refer to the Outline for a more detailed breakdown of the document.

Refer to this separate document (more) for details about how to conduct a sine sweep test that can be used with this study.

Quick Links

In the future this will point to resources that readers of this document like to have readily available. Follow the Notes link above to add suggestions and see what resources have already been proposed.

Introduction

A revision of ASTM E467 was started in 2023(?). The motivation was to make it less cumbersome for independent labs to apply. Due to their frequent test machine configuration and test profile changes, the original premise of E467 to test each setup was problematic. It had not been a significant issue until recently since standards that referenced E467 only indicated that users should do the verification. Recently those documents changed from should to shall. Now auditing of compliance was required and issues arose.

During the process of drafting revisions, it became clear that some allowance was needed to allow users to justify not repeating a verification for a certain window of changes around a verified operating point. Expanding use of the accelerometer method was one path of revision. That holds some appeal due to more flexibility regarding the reference device (one standard accelerometer vs multiple custom dynamometer). Alas it does still require a lab to have the time and expertise to perform a verification test each time a configuration/testing profile changes.

This document is exploring the use of a sine sweep profile rather than a single frequency test when using a dynamometer. Wording has already been added to E467 suggesting that small deviations in configuration and/or test plan will not require a new verification. Unfortunately that still leaves the ambiguity of how much variation is still a small deviation. At the current time, preliminary testing with a sine sweep profile shows a high likelihood that data for numerous test conditions can be obtained in a single system setup and test run. It is believed that this data can then be analyzed when it is needed in order to justify an operating point that deviates from a formally verified operating point (configuration and test plan).

Analysis Families

Up / Next / Notes / Down / All

Once a sine sweep has been completed, the data acquired can be analyzed to determine various system characteristics and behaviors. The list below takes you to more in-depth discussions of specific analysis types. Click Next in the line of links just below this section’s heading to go to the analysis catalog.

Dynamic Force Measurement Verification

ASTM E467 describes a method for evaluating the dynamic force measurement accuracy for one specific operating point. In the interest of minimizing the time and expense associated with performing an evaluation it is desirable to gather as much information as practical during one test machine setup. Whereas the current standard (2024) is written around running the test machine at a single frequency and amplitude when collecting data, recent experiments show the strong possibility that a large quantity of data could be collected using a sine sweep and then only analyzing a subset of that data for any particular operating point.

Inertial Measurement Error Assessment

TBD: This will explain how to go about a sine sweep analysis in order to define the amount of force measurement error related directly to test machine vibration.

Analysis Catalog

Up / Next / Notes / Down / All

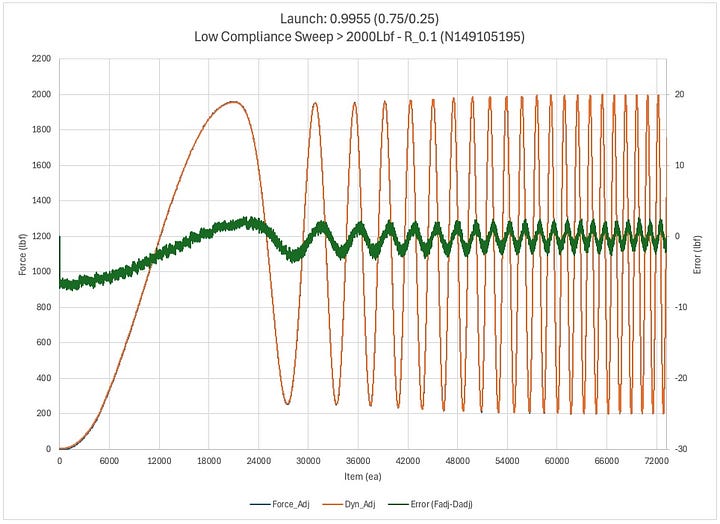

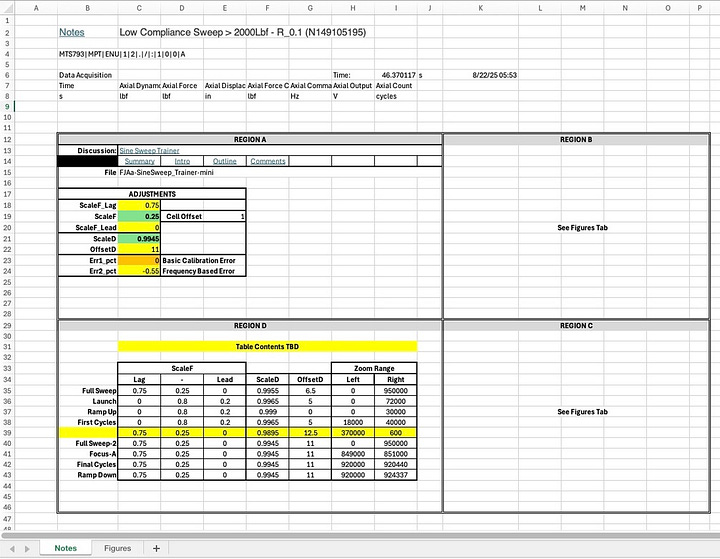

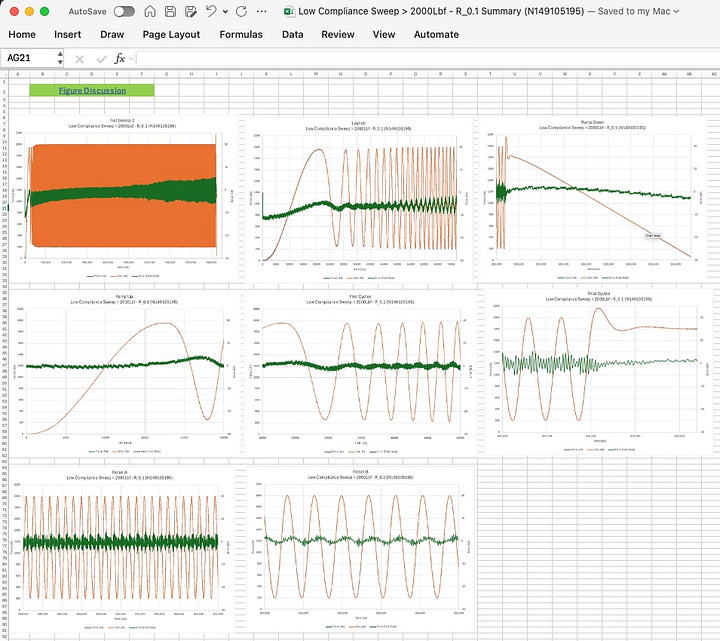

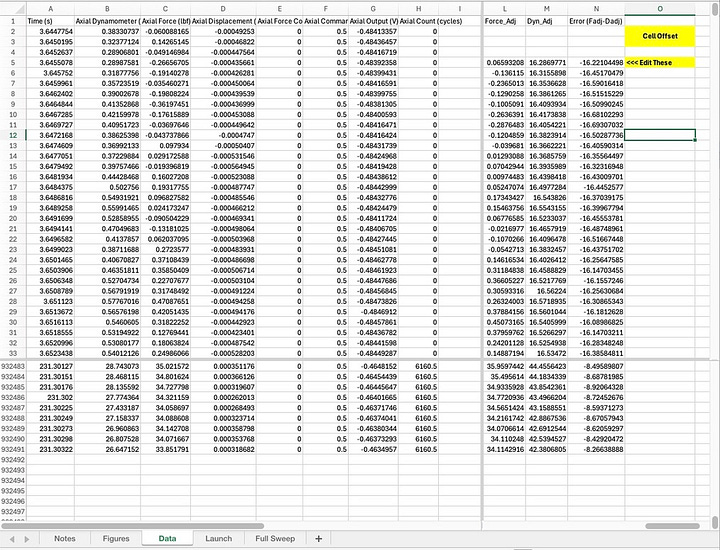

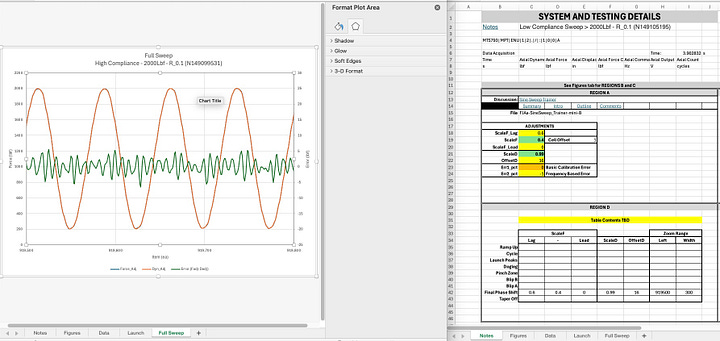

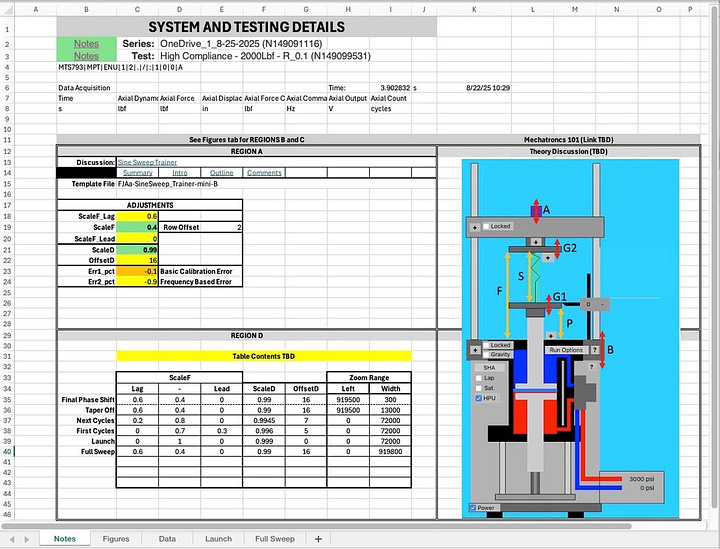

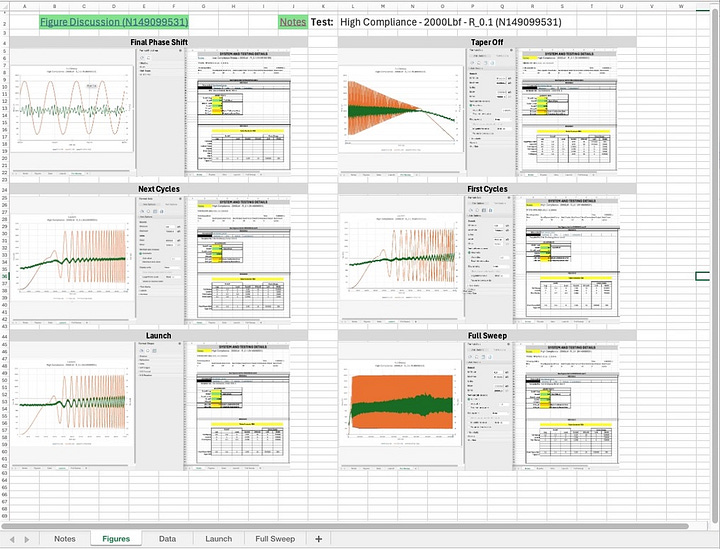

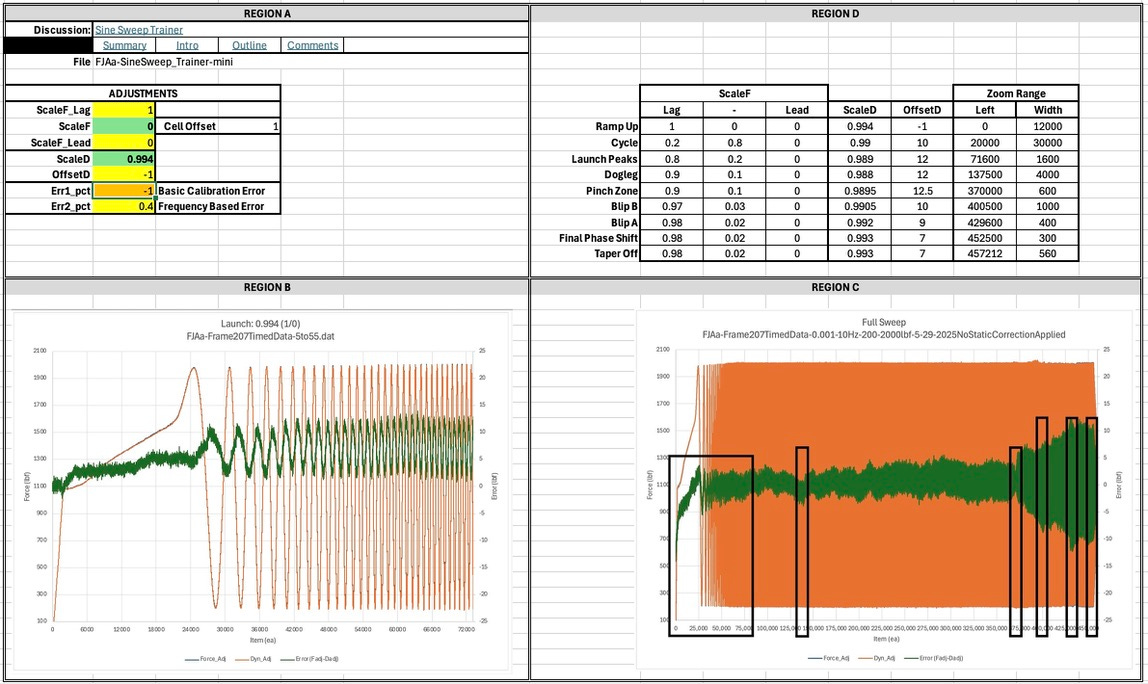

Analysis can be done using an Excel workbook. The set of 4 images below show the primary aspects of an analysis. Refer to the Sine Sweep Trainer (more) for an in depth discussion of this summary graphic. NOTE: The graphic is evolving regularly as more tests are done. Be sure to check back regularly for the latest version.

While a sine sweep gathers significantly more test machine performance information that operation at a single point, it is still far short of what is needed to fully understand the operating envelope of a material test system. The following figure shows 5 different classic operational sweeps (A-E) for a material test system. Curves F and G show representative force error profiles that are due to the inertial movement of the test frame during dynamic operation.

Characteristic Waveforms

Due to the large amount of information that can be presented about any one waveform, this section is only going to mention highlights of various waveforms. Then there will be a link to the primary material. Over time as the most important material is identified, a separate effort may be conducted to create an archival document.

Force Measurement Errors

Ramp Up

PVS002f: TBD (discussion)

Cycle

PVS002f: TBD (discussion)

Launch Peaks

PVS002f: TBD (discussion)

Pinch Zone

PVS002f: TBD (discussion)

Blip B

PVS002f: TBD (discussion)

Blip A

PVS002f: TBD (discussion)

Taper Off

PVS002f: TBD (discussion)

Inertial Forces

Machine Evaluations

5 - 55 hz

Outline

Getting Started

Up / All / Notes

Summary Report

Up / All / Notes: <Tasks>

ID: N154915265

Introduction-Report

Up / All / Notes

The summary report is a two page document that highlights the findings of a test machine’s analysis. This section gives guidance as to how to use that report. Refer to Proposed Process for how to gather the data initially. (More TBD)

Core report images

Up / All / Notes

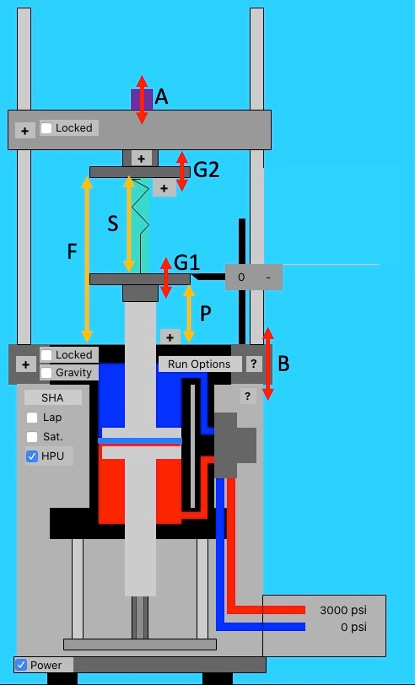

Upper Left: Test Machine (Notes)

Upper Right: Sine Sweep startup (Notes)

Lower Left: Summary Report settings (Notes)

Lower Right: Summary Report typical images (Notes)

Computer Simulation

Up / All / Notes

Mechatronics 101 can be used to perform test machine simulations. Contact Joe Albright for details.

Project Notes

Creating this document will be a multi-month, if not multi-year endeavor. It will require the input of many participants. In order to help keep the team focused and readers informed of current activities, this section has been created.

Status

As of 250721: This section has been started as an aid to guiding our upcoming machine testing. Considerable document editing was done in recent days so that this can evolve as our primary document. The main focus of this project is to create the Analysis Catalog that can be used by the team currently revising ASTM E467. The catalog is intended to give them technical support for approaches they wish to add to the procedure.

Releases

First bundle: N156213236 < fjaa250915 (Notes)

Plans

Up / Notes / Next / Down / All

Goals

Refine sine sweep method

Identify critical sweeps for system characterization

Other TBD?

Overview

The general plan is to have participants run sine sweep tests on machines they have readily available. Configurations are ones that are important to them. Dynamometers initially will simply be what they have at their disposal. After a period of time, if it appears that some more unique dynamometers are needed to test special conditions, those might be made by (???) and shared in round robin style with the participants.

Deliverables

There are nominally 3 deliverables for each sine sweep performed.

Test data file

Analysis workbook

Analysis report(s)

Task Notes

Up / Notes / Next / Down / All

The bulk of the project management documentation will be in the comments section and references linked to from there. Those references can be a variety of traditional targets. There will also be some links that point to keyword searches for specific email threads. This is anticipated to allow the team to stay flexible and efficient while not losing robust connections between our working notes and this final deliverable.

Milestone Progress

Initial Sine Sweep testing performed (Notes)

Sine Sweep Instructions written (Notes)

Preliminary machine evaluations performed (Notes)

More TBD (Notes)

Team Activities

This is the gateway for notes that each team member controls related to what they are doing on the project. Each person’s note link goes to a Substack comment associated with this document. There the members will do some combination of directly adding notes and/or linking to other resources where they have the material they wish to share. It has been structured in this manner so all readers of this document know how to follow the basic information flow, while leaving each team member free to use the resources that are best suited to them.

Team Help

See the Notes for help with using this document. Other topic specific help will generally be provided with the Notes for that topic.

Events

Up / Notes

TBD

Individuals

Up / Notes

Summary Report (N154915265)

********

This section is for defining and explaining the summary report of a system test. Replies to this comment list things like tasks remaining to be done, improvements needed, and items to correct/expand.

********

Up:

TBD

Project Notes

Tag4u: N137896974

********

Read the replies to this comment for detailed discussions of this document section.

Use the “Top” link below to jump to the top of the Substack post that corresponds to this comment.

========

Top: https://albrightj.substack.com/i/168894224/project-notes